1. Introduction: Why Temperature Matters for Concrete Pump Hoses

The concrete pump hose is a critical component in concrete delivery systems, widely used in construction projects such as high-rise buildings, tunnels, and bridges. However, many users overlook the significant impact of ambient temperature on the hose’s performance and service life.

This article will analyze in detail how high and low temperatures affect concrete hoses and provide professional usage recommendations and hose selection guidelines to help you ensure safe and efficient construction operations.

2. Effects of High Temperatures on Concrete Hoses

2.1 How Heat Affects Hose Material

In hot weather conditions, especially when ambient temperature exceeds 35°C (95°F), concrete hoses may experience the following issues:

-

Rubber softening, reducing pressure resistance

-

Delamination risk between the inner rubber layer and steel reinforcement

-

Surface aging and cracking

-

Decreased abrasion resistance and shortened lifespan

Test data shows: When the surface temperature of a concrete hose exceeds 60°C (140°F), abrasion resistance decreases by approximately 20%, and adhesive strength between layers drops by 15%.

2.2 Real-World Case

In 2023, at a Southeast Asia construction site, long-term exposure to 40°C (104°F) sunlight caused the concrete pump hose to develop bulging at the bend. Inspection revealed delamination between the inner and outer rubber layers, resulting in economic losses and project delays.

2.3 Recommendations for High-Temperature Conditions

✅ Store hoses in shaded areas, avoid direct sunlight

✅ Use sunshades or covers during operation

✅ Select high-temperature resistant concrete hoses (such as EPDM rubber hoses)

✅ Limit continuous pumping duration to prevent overheating

✅ Check hose surfaces daily for signs of aging or cracks

3. Effects of Low Temperatures on Concrete Hoses

3.1 Risks of Low Temperatures

In cold environments, especially when the ambient temperature drops below 0°C (32°F), concrete hoses may face the following challenges:

-

Rubber hardening and loss of flexibility

-

Cracking at bends

-

Increased flow resistance and risk of blockages

-

Permanent deformation (collapse at bends)

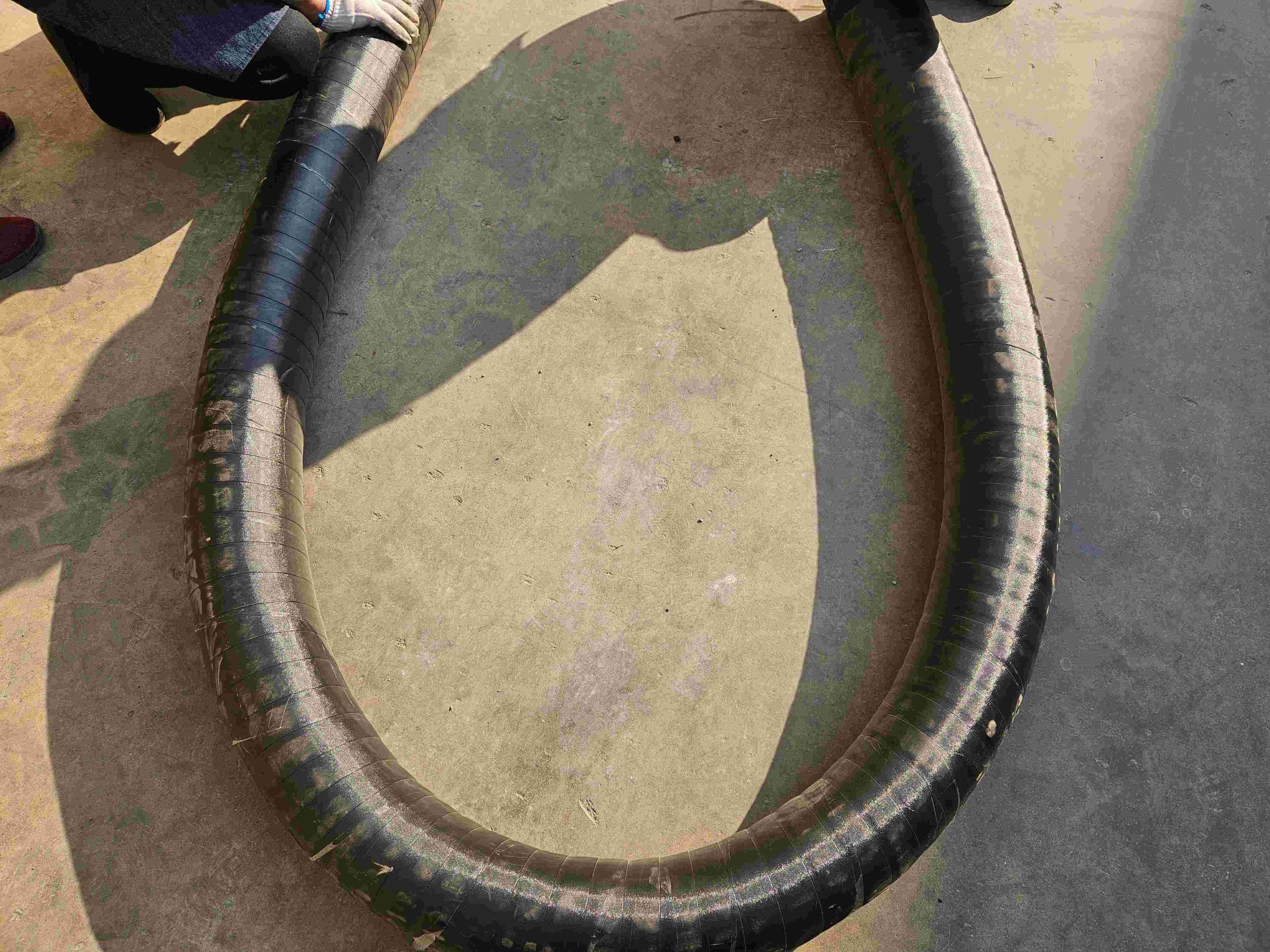

Data shows: In low-temperature conditions, the flexural fatigue life of standard concrete hoses decreases by 30%-40%.

3.2 Real-World Case

At a construction site in Heilongjiang, China, during winter conditions at -20°C (-4°F), the concrete pump hose cracked during its first bend due to lack of preheating, leading to direct product failure.

3.3 Recommendations for Low-Temperature Operation

✅ Preheat hoses in indoor environments at 5°C20°C (41°F68°F)

✅ Avoid ice formation on the hose surface

✅ Choose low-temperature resistant concrete hoses (e.g., NBR+PVC composite hoses)

✅ Avoid rough handling, sharp bends, or heavy pressure on hoses during cold weather

✅ Regularly inspect hoses for signs of brittleness or cracks

4. Impact of Temperature Fluctuations on Concrete Hoses

In regions with significant day-night temperature differences, such as deserts and plateaus, temperature fluctuation can exceed 25°C (45°F), leading to:

-

Repeated thermal expansion and contraction, accelerating fatigue

-

Microcracks propagation

-

Adhesion weakening between layers, causing premature aging

Recommended Measures: ✅ Inspect hoses daily for signs of cracking

✅ Avoid overnight outdoor storage

✅ Use hoses with high-strength steel wire reinforcement for improved structural stability

5. Temperature Effects on Hose Storage and Transportation

5.1 Storage Temperature Requirements

Recommended storage environment: 5°C25°C (41°F77°F)

Avoid:

❌ Long-term exposure to direct sunlight

❌ Freezing environments

❌ Humid or chemically corrosive environments

5.2 Storage & Transportation Guidelines

✅ Store hoses naturally coiled, avoid over-bending

✅ Inspect hose surfaces regularly for aging or cracks

✅ If stored for over 3 months, conduct a thorough inspection before use

6. Concrete Hose Selection Guide for Different Temperature Conditions

| Working Environment | Recommended Hose Material | Temperature Range | Features |

|---|---|---|---|

| Normal Conditions | NR+SBR Blended Rubber | -10°C~50°C | Cost-effective, good abrasion resistance |

| High Temperature | EPDM or Heat-Resistant Synthetic Rubber | 0°C~80°C | High heat resistance, anti-aging |

| Low Temperature | NBR+PVC Cold-Resistant Rubber | -30°C~40°C | Flexible in cold weather, crack-resistant |

| Large Temperature Variation | Steel Wire Reinforced Hose | -20°C~60°C | High structural stability, fatigue-resistant |

7. Conclusion: Manage Temperature Risks and Ensure Safe Operation

Ambient temperature significantly affects the performance and lifespan of concrete pump hoses. From selection, storage to daily use, temperature factors should always be considered. Ignoring temperature-related risks can lead to hose failure, work stoppages, and even safety incidents.

By choosing the right hose, following proper maintenance protocols, and adjusting usage habits according to temperature conditions, you can effectively minimize these risks and extend the service life of your concrete hoses.

8. Frequently Asked Questions (FAQ)

Q1: What is the temperature resistance range of concrete hoses?

Standard NR+SBR concrete hoses typically operate within -10°C to 50°C (14°F to 122°F). For higher or lower temperatures, specialized high-temperature or cold-resistant hoses are recommended.

Q2: How long will hoses age if stored in high temperatures?

When exposed to long-term sunlight at temperatures over 40°C (104°F), concrete hoses may show signs of aging and surface cracks within 3-6 months.

Q3: Is preheating necessary for concrete hoses in cold environments?

Yes. When operating below 0°C (32°F), it is recommended to preheat hoses indoors for at least 24 hours to avoid cracking due to brittleness.

Q4: What are the safety risks of temperature fluctuations?

The main risks include softening, hardening, delamination, cracking, and hose collapse. In extreme cases, temperature-related failures may cause hose bursts and safety hazards.