In concrete pumping applications, the wear resistance and service life of hoses are crucial. Many people assume that “the thicker the inner rubber, the better the concrete hose quality”, but this is not entirely true! The quality of the rubber material is the key factor affecting the hose’s lifespan.

This article will guide you on how to distinguish a high-quality concrete hose from a poor one based on its texture, elasticity, smell, and appearance, helping you make the right choice.

1. Texture Test: Feel the Inner Rubber

✅ High-Quality Inner Rubber: Feels smooth and fine, with good elasticity. When pressed, it quickly returns to its original shape, indicating high wear resistance and durability.

❌ Low-Quality Inner Rubber: May feel rough, sticky, or grainy, suggesting poor-quality fillers and low wear resistance.

💡 Tip: If the rubber recovers slowly or does not bounce back after pressing, it indicates aging or inferior quality, significantly shortening the hose’s lifespan.

💡 If the rubber feels overly hard and lacks elasticity when pressed, it likely contains excessive fillers, making it prone to cracking or breaking during use.

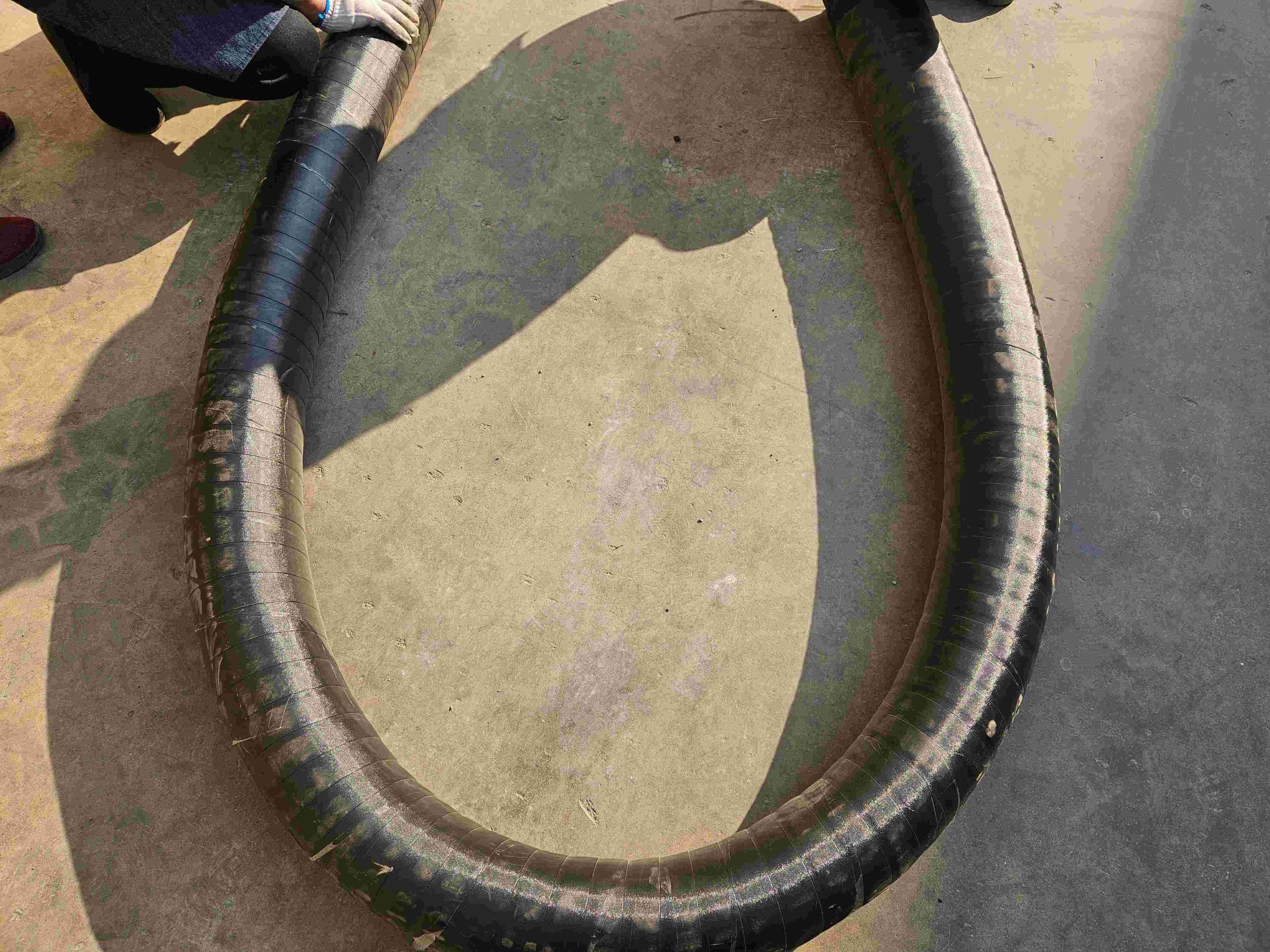

2. Elasticity Test: Bend the Hose

✅ High-Quality Inner Rubber: Bends smoothly with good flexibility, without feeling too stiff or too soft.

❌ Low-Quality Inner Rubber:

- Too hard: Often made from inferior rubber, which increases the risk of cracking.

- Too soft: May contain excessive fillers, resulting in poor wear resistance and lower pressure tolerance.

💡 Tip: A hose with good flexibility can effectively absorb vibrations and impacts, extending its lifespan.

3. Smell Test: Sniff the Rubber

✅ High-Quality Inner Rubber: Has only a mild rubber scent, without a strong chemical odor.

❌ Low-Quality Inner Rubber: May emit a strong chemical smell, indicating the presence of recycled rubber or excessive chemical additives, which can cause premature aging and cracking.

💡 Tip: If the rubber gives off a strong, irritating odor, it is best to avoid it.

4. Visual Inspection: Check the Color and Surface

✅ High-Quality Inner Rubber: Even color, smooth surface, and a slight sheen, indicating high-quality rubber composition.

❌ Low-Quality Inner Rubber: Dull color, may have black spots, bubbles, or uneven particles, which are signs of poor-quality fillers or recycled rubber.

💡 Tip: Lightly scratch the surface. If powder or particles fall off, the rubber quality is likely poor.

5. Thickness ≠ Quality – The Key Is the Material!

Many people mistakenly believe that a thicker inner rubber layer means better durability, but in reality:

- Low-quality hoses: Some manufacturers increase thickness to compensate for poor rubber quality, but due to low wear resistance, the hose still wears out quickly.

- High-quality hoses: Even with a thinner inner rubber layer, premium natural rubber or SBR (styrene-butadiene rubber) provides better wear resistance and tear strength, resulting in a longer lifespan.

✅ Our concrete hoses have a thinner inner rubber layer compared to some competitors, but due to our use of premium rubber and advanced manufacturing techniques, they last longer!

Conclusion: How to Choose a High-Quality Concrete Hose?

1️⃣ Touch it – Smooth, fine texture with elasticity, not sticky or rough.

2️⃣ Press it – Quickly bounces back, soft yet firm, ensuring better durability.

3️⃣ Smell it – Mild rubber scent, without strong chemical odors.

4️⃣ Inspect it – Even color, no bubbles, no impurities.

5️⃣ Don’t be misled by thickness – Focus on rubber quality, not just thickness.

📢 Choose the right hose for safer, more efficient, and longer-lasting concrete pumping!

If you’re looking for high-quality concrete hoses, feel free to contact us. We offer professional solutions tailored to your needs!

📞 Phone: 008615066401151

📧 Email: lee@zhong-liao.com

🌐 Website: www.zhong-liao.com