Introduction

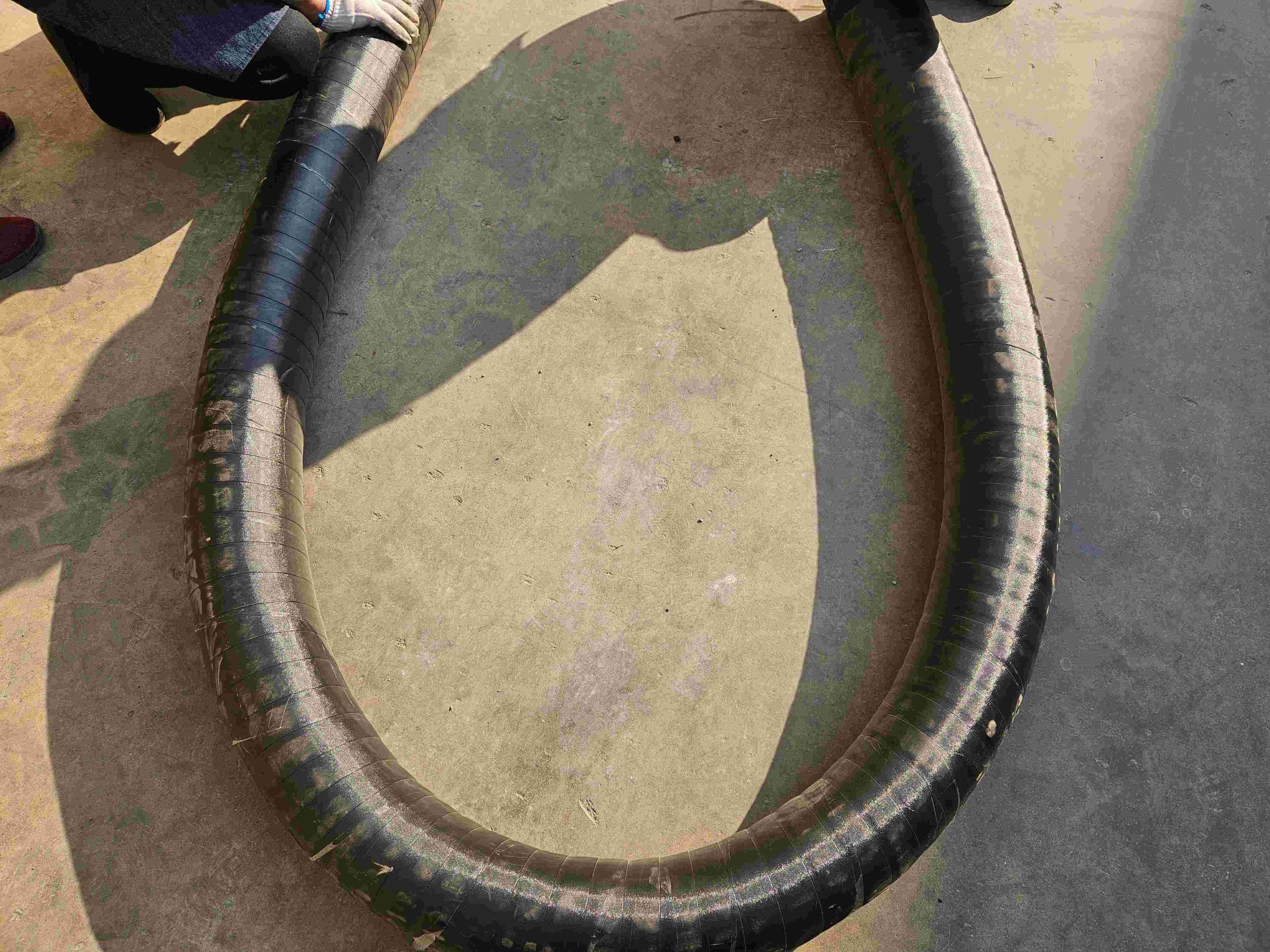

Concrete hoses play a crucial role in construction projects, especially in high-pressure pumping systems. They are responsible for the efficient transportation of concrete, but due to continuous exposure to high pressure, abrasion, and harsh environments, these hoses often wear out faster than expected.

Frequent hose replacements increase costs and delay construction timelines. So, how can you extend the lifespan of concrete hoses, minimize replacement frequency, and reduce maintenance expenses?

This guide provides professional insights on choosing the right hose, proper usage, maintenance, and storage techniques to help you maximize durability.

1. Choose High-Quality Concrete Hoses

The first step to extending hose lifespan is selecting the right product. Poor-quality hoses tend to deteriorate quickly, so it’s essential to consider the following factors:

✅ 1.1 Hose Material

- High-Abrasion-Resistant Rubber Lining – A durable rubber inner lining reduces wear caused by concrete particles.

- Reinforced High-Strength Layers – Hoses with steel wire or synthetic fiber reinforcement can withstand higher pressure and prevent bursting.

- Anti-Static Properties – Some applications require anti-static materials to reduce safety risks.

👉 Recommended: High-Quality 5-Inch Concrete Pump End Hose

✅ 1.2 Hose Length and Diameter

- Choose a length that suits the worksite to prevent excessive bending or increase in pumping resistance.

- Match the hose diameter with pump equipment specifications to ensure optimal pumping efficiency.

2. Proper Usage of Concrete Hoses

Even high-quality hoses won’t last long if misused. Here’s how to handle them properly:

✅ 2.1 Avoid Exceeding Pressure Limits

- Every concrete hose has a rated pressure range; always ensure your system doesn’t exceed the limit.

- Continuous high-pressure operation accelerates hose wear and aging.

✅ 2.2 Minimize Bending and Twisting

- Avoid excessive bending as it accelerates internal lining wear.

- The bending radius should be no less than six times the hose diameter to prevent inner wall damage.

✅ 2.3 Secure and Connect Properly

- Before operation, check hose connections to prevent leaks.

- Use proper hose brackets to avoid suspension stress, which can lead to cracks.

👉 Recommended: Complete Guide to Concrete Pump End Hoses

3. Daily Maintenance & Cleaning

Routine cleaning and inspections are key to maximizing hose lifespan.

✅ 3.1 Daily Cleaning

- Flush hoses immediately after each use to prevent concrete buildup.

- Use high-pressure water flushing or sponge ball cleaning methods to keep the hose interior clean.

✅ 3.2 Regular Inspections

- Before each use, inspect for wear, cracks, or deformations.

- Pay special attention to hose ends, as they are more prone to damage.

✅ 3.3 Timely Replacement of Worn Parts

- If the inner lining is worn more than 30%, replace the hose to prevent leaks or bursts.

- Minor damages can be repaired, but significant wear requires full hose replacement.

4. Proper Storage Methods for Concrete Hoses

Incorrect storage leads to aging, hardening, and loss of flexibility, reducing hose lifespan.

✅ 4.1 Keep Away from Direct Sunlight

- Long-term exposure to sunlight causes rubber aging. Store hoses in cool, dry areas.

- Use protective covers or tarps to shield hoses from UV rays.

✅ 4.2 Avoid Heavy Stacking

- Never pile hoses too high, as excessive weight can cause deformation.

- Use hose racks or hangers to store them in a natural position.

✅ 4.3 Periodic Inspection

- Check hoses periodically for hardening, cracks, or deformation and take action if necessary.

5. Use High-Quality Fittings & Proper Installation

Aside from selecting a high-quality hose, using durable fittings and proper installation is crucial for longevity.

✅ 5.1 Choose Durable Hose Fittings

- Opt for high-pressure-resistant, rust-free materials such as stainless steel or alloy fittings.

- Regularly check and tighten fittings to prevent leaks.

✅ 5.2 Install Seals Correctly

- Ensure seals are intact and undamaged to prevent leakage or blockages.

- Use the right size seals to maintain a secure fit and prevent premature wear.

👉 Recommended: Explore High-Quality Concrete Hoses

Conclusion

The lifespan of concrete hoses depends on product quality, proper usage, regular maintenance, and correct storage methods. By choosing durable hoses, following correct operational guidelines, and conducting routine inspections, you can significantly improve their longevity, reduce costs, and enhance efficiency.

🚀 Looking for high-quality, long-lasting concrete hoses? Check out our premium selection!

👉 5-Inch Concrete Pump End Hose

👉 Complete Concrete Pump End Hose Series

👉 Discover More Concrete Pumping Solutions