Overview

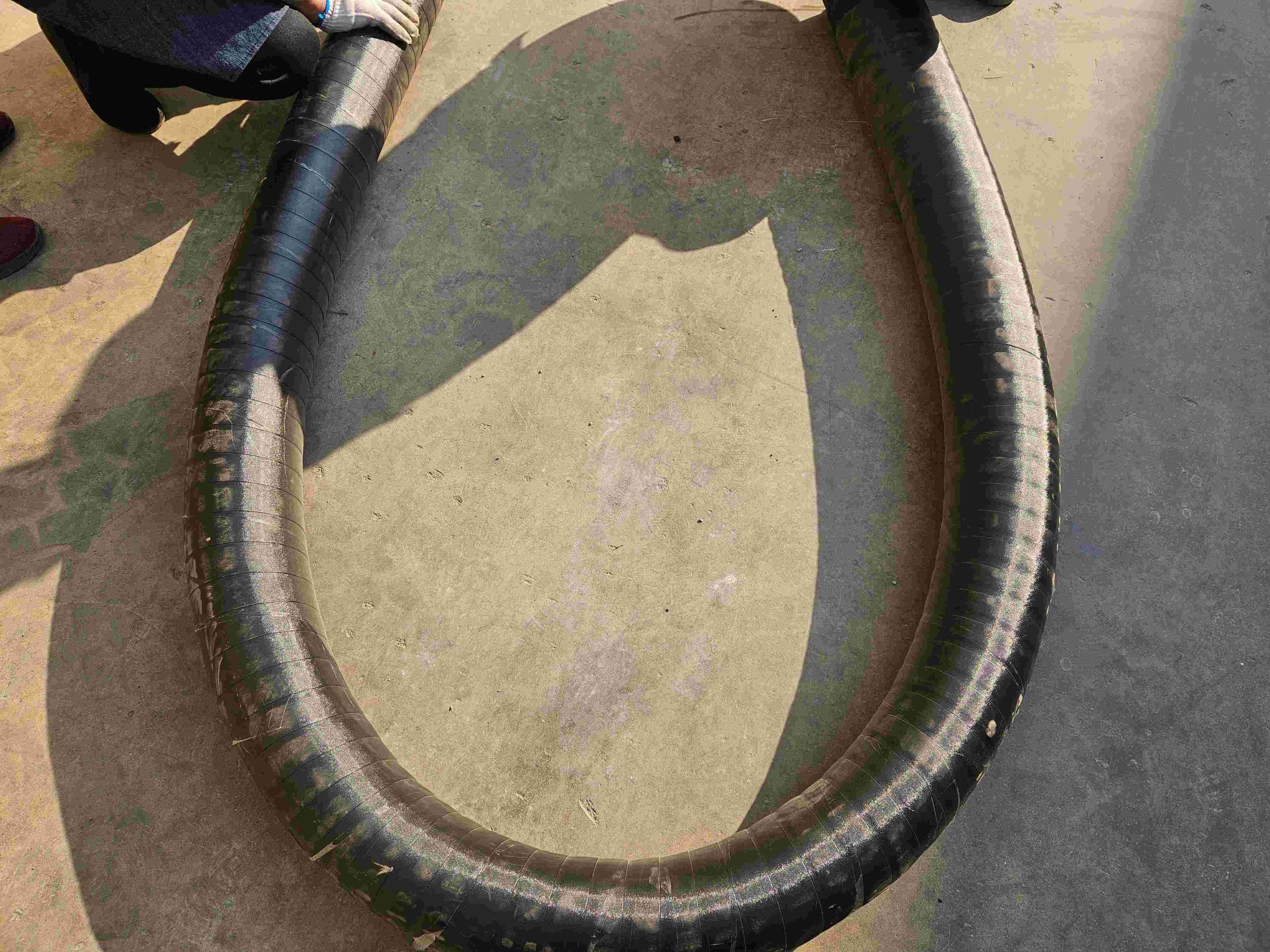

The Mud Hose is a critical component in the Diaphragm Wall Cutter’s reel system, specifically designed for transporting and circulating slurry during construction. Unlike traditional hoses laid on the ground, this type of hose is engineered for dynamic operation within the reel system, where it plays a vital role in maintaining operational efficiency and construction precision.

1. Functions of Mud Hose in the Reel System

Slurry Transportation

- The hose transfers slurry from the pump to the cutter head through the reel system, ensuring trench wall stability during excavation.

- It supports efficient slurry circulation within a closed system, minimizing site contamination.

Slurry Return

- It facilitates the return of slurry containing debris and sand to the treatment unit, maintaining environmental cleanliness and operational efficiency.

Flexible Deployment

- The hose dynamically winds and unwinds with the reel system, adapting to the cutter’s working depth and ensuring uninterrupted construction.

2. Key Performance Requirements of Mud Hose

High Abrasion Resistance

- The inner lining must withstand the abrasive nature of slurry, often containing sand and gravel.

Flexibility and Tensile Strength

- The hose must be highly flexible to endure repeated winding and unwinding while maintaining tensile strength to prevent damage during deep trench operations.

High-Pressure Resistance

- The hose should handle the high pressure typical in reel systems, often ranging from 20-50 Bar.

Corrosion and Aging Resistance

- Materials should resist corrosion caused by chemical additives in the slurry and endure harsh environmental conditions like extreme temperatures and humidity.

3. Installation and Operational Guidelines

Installation in the Reel System

- Steps: Secure the hose firmly onto the reel system and ensure tight and leak-free connections with equipment interfaces.

- Testing: After installation, operate the reel system to ensure smooth winding and unwinding without twisting or jamming.

During Operation

- Monitor Reel Tension: Avoid excessive tension that could damage the hose.

- Prevent Sharp Bends: Ensure the bending radius meets product specifications to avoid permanent damage.

Adapting to Cutting Depth

- Adjust the reel tension according to the trench depth to maintain optimal hose performance, avoiding slack or over-tightening that could lead to wear.

4. Maintenance and Care

Daily Maintenance

- Cleaning: Flush the hose thoroughly with clean water after each use to remove slurry residues and debris.

- Visual Inspection: Check the hose surface for cracks, tears, or signs of wear and promptly repair or replace damaged sections.

Periodic Maintenance

- Pressure Testing: Conduct monthly pressure tests to ensure the hose can handle operational demands.

- Lubricating the Reel System: Regularly lubricate the reel’s moving parts to minimize wear on the hose.

Replacement Schedule

- Set a replacement schedule based on usage intensity and wear levels (recommended evaluation after 300-500 hours of operation).

5. Common Issues and Solutions

Excessive Hose Wear

- Cause: High gravel content in the slurry or improper reel operation.

- Solution: Optimize slurry filtration and adjust reel tension to reduce abrasion.

Hose Winding Issues

- Cause: Misalignment of the reel system or excessive bending of the hose.

- Solution: Realign the reel system and reposition the hose for smoother operation.

Leakage

- Cause: Loose connections or aging of the hose.

- Solution: Replace sealing elements or aged hose sections.

6. Purchasing Recommendations

Material Selection

- Choose hoses made from high-abrasion-resistant synthetic rubber or polyurethane for superior performance in reel systems.

Reliable Suppliers

- Purchase from certified manufacturers or suppliers to ensure compliance with industry standards (e.g., ISO, DIN certifications).

Custom Sizing

- Ensure the hose’s length, diameter, and fittings match the equipment to avoid operational mismatches.

7. Conclusion

The Mud Hose is an indispensable component of the Diaphragm Wall Cutter’s reel system, directly impacting operational efficiency and equipment lifespan. Proper selection, installation, and maintenance can significantly improve construction quality and reduce operational costs. Whether for foundational work or complex terrain projects, understanding best practices for mud hoses will ensure reliable and efficient operations. For additional technical support or product recommendations, consult professional suppliers for tailored solutions.