Introduction

Concrete pumping is a crucial process in modern construction, enabling quick and efficient transportation of concrete. A key component in this system is the concrete pump end hose, which plays a vital role in directing the flow of concrete to the desired location. But did you know that the choice of hose can significantly impact both the efficiency and safety of your project? In this guide, we’ll dive deep into the types, uses, and maintenance of concrete pump end hoses to help you make informed decisions. Whether you’re a contractor or just curious about concrete pumping, this article will provide valuable insights!

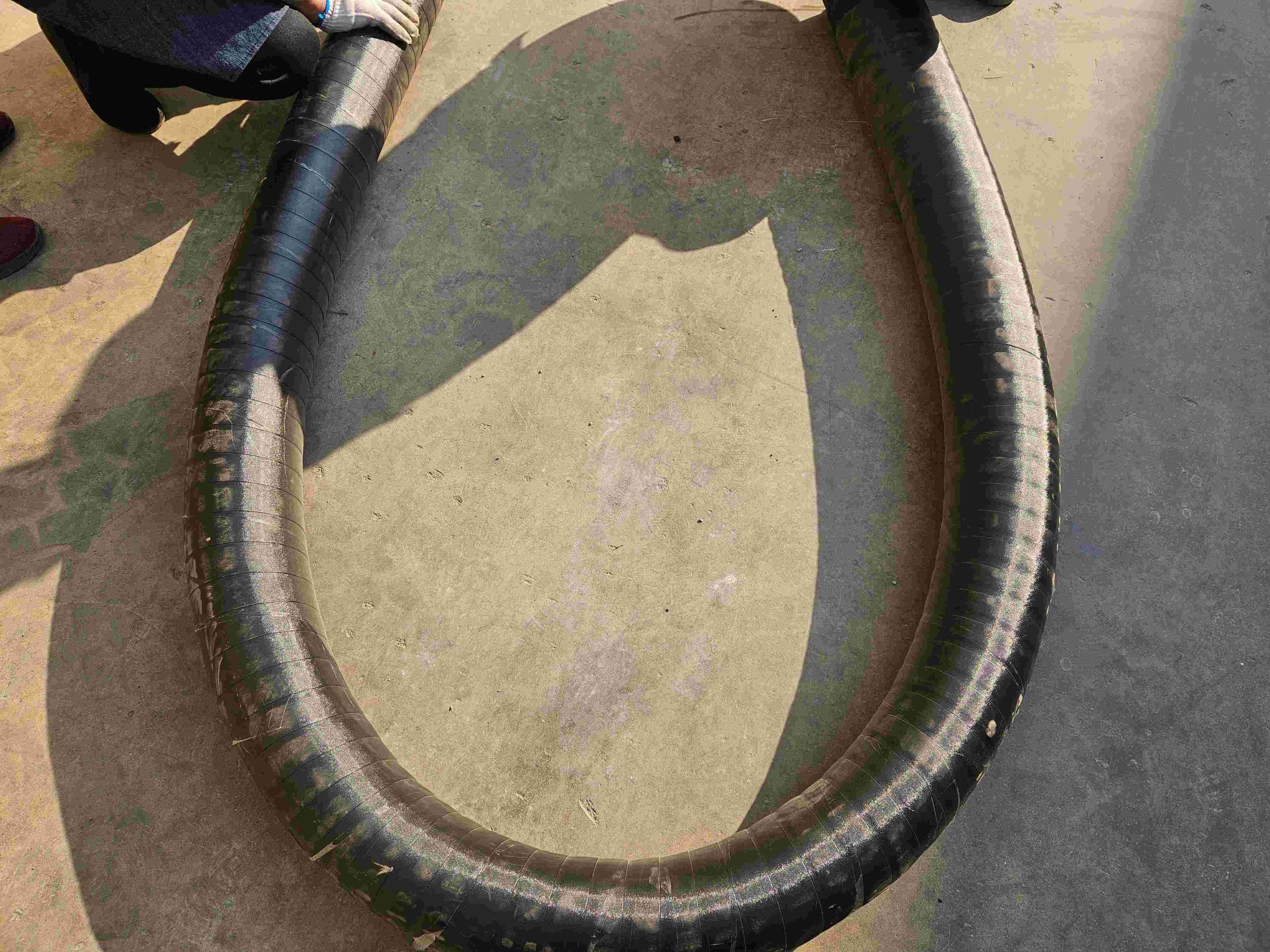

What is a Concrete Pump End Hose?

- Definition and basic function: Understanding the primary role of the concrete pump end hose in the pumping system.

- Components and design features: Exploring the construction and materials used in concrete pump end hoses.

- Why it’s essential in pumping concrete: Discussing how the hose contributes to the overall efficiency and safety of concrete pumping.

Types of Concrete Pump End Hoses

- Rubber hoses: Benefits and common uses, including flexibility and durability.

- Steel-reinforced hoses: Strengths of these hoses, ideal for heavy-duty applications.

- Twin line hoses: Explanation of twin line hoses and how they differ from standard hoses.

- Lay-flat hoses: Why lay-flat hoses are a popular choice for smaller, portable concrete pumps.

- Custom hoses: When and why you might need a custom concrete pump end hose.

Common Uses of Concrete Pump End Hoses in Construction

- High-rise building projects: How pump end hoses are essential for reaching high levels.

- Road and highway construction: The role of hoses in ensuring efficient concrete delivery in complex terrains.

- Foundation and slab work: Using the hose for pouring concrete in foundations and large slabs.

- Tunnel and mining projects: Adaptations for underground or hard-to-reach areas.

- Residential construction: The use of end hoses for smaller residential projects.

Key Factors to Consider When Choosing a Concrete Pump End Hose

- Size and length: How to choose the right hose size based on the job’s requirements.

- Pressure and strength rating: Why these ratings matter for safety and performance.

- Material durability: Choosing between rubber, PVC, and other materials for longevity.

- Flexibility vs. rigidity: Finding the right balance based on your worksite’s needs.

- Weather conditions: Considering how extreme temperatures impact hose performance.

Maintaining and Extending the Lifespan of Concrete Pump End Hoses

- Proper cleaning and flushing: Best practices for cleaning hoses to avoid blockages.

- Inspection and maintenance schedules: How to regularly inspect for wear and tear.

- Storage tips: Storing hoses correctly to prevent damage.

- Signs of damage or wear: How to spot the early warning signs that your hose may need replacement.

- Reinforcing safety protocols: Ensuring hose safety on the job site to prevent accidents.

Conclusion

Concrete pump end hoses are integral to the efficiency and safety of concrete pumping operations. Whether you’re a seasoned professional or just starting in the construction industry, understanding the types, applications, and maintenance of these hoses will help you optimize your projects. Make sure to choose the right hose, maintain it properly, and always keep an eye out for any signs of damage to keep your concrete pumping system running smoothly. Ready to invest in the right equipment for your next job? Check out our recommendations for the best concrete pump end hoses in 2025!